Welcome to Section View, a newsletter for curious engineers and hardware people. Brought to you with ❤️ by the Five Flute team.

Designer’s Corner

The OG of precision measurement

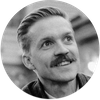

Apparently, some people think that James Watt created a micrometer 75 years before anyone else did it. That’s completely wild to me! I really dig anything related to the origins of precision and this video from machine thinking on the Watt micrometer is just awesome.

I found the plans online as well and put them up on Five Flute with a few comments highlighting interesting aspects of the design. Check it out in this shared drawing review.

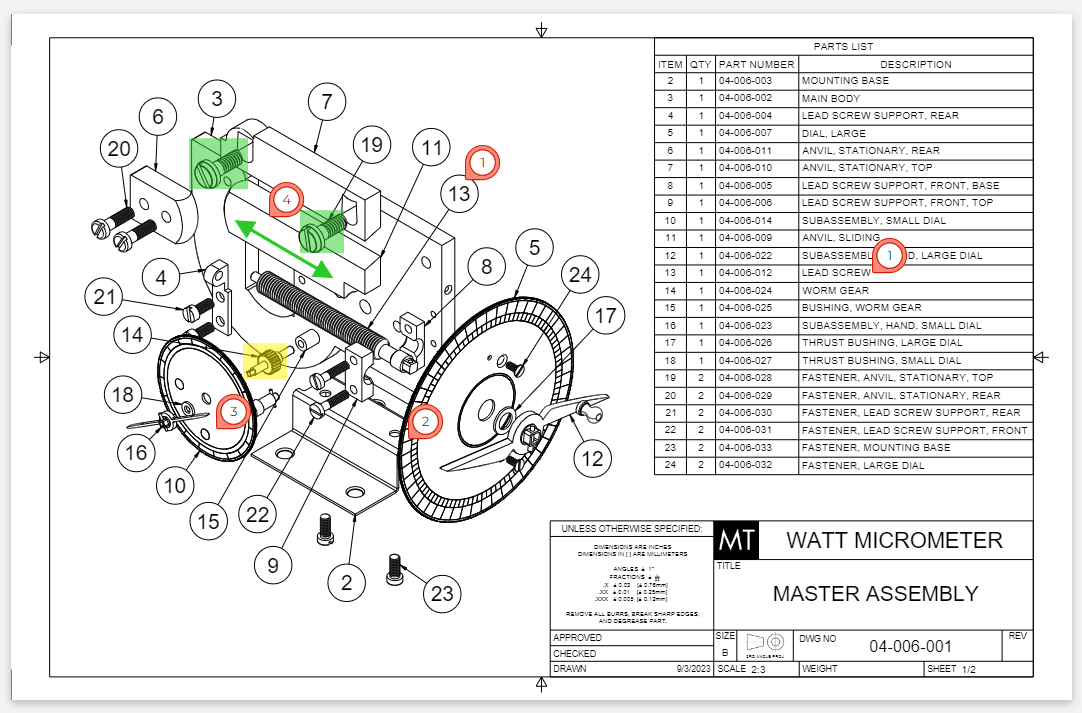

Rolling contact joints

Breaking Taps has a nice video that goes into detail on the design of rolling contact joints. I haven’t done much robotics work at the micro scale, so its interesting to see the solutions folks come up with when things get really small. The video is great because he shows off a scale model to introduce the key design concepts and assembly. My favorite part of these joints is that you can design the contact surfaces to achieve a specific range of motion in a very elegant way. In a lot of ways its like a knee joint with cruciate ligaments (ACL, MCL, PCL) all acting to kinematically define the motion profile. Very bio inspired, very elegant.

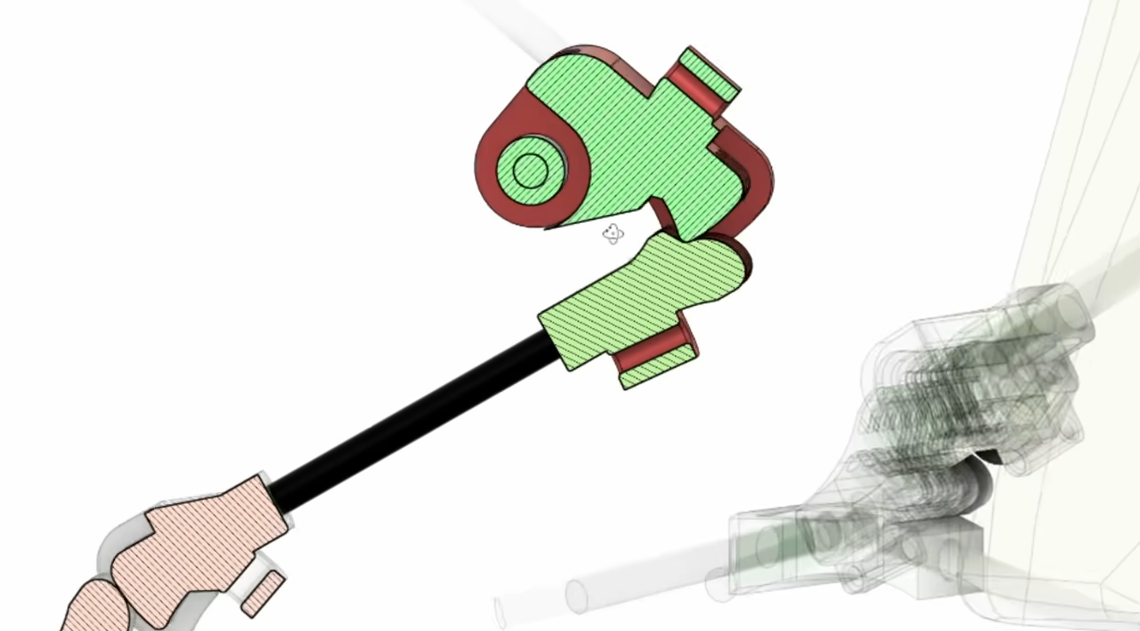

Roller screws vs ball screws

I’ve designed lots of automation equipment throughout my career and yet somehow I’ve never spec’d or purchased a planetary roller screw. Honestly anything with a planetary gearbox gets my attention because I’m just a simple mech E (see spinny thing,…spinny thing good!), but roller screws are genuinely cool.

This video has a great overview for all you working machine designers out there.

TL;DW: Here’s my important takeaways from the video.

- The depth of hardened material on a planetary roller screw is orders of magnitude greater than on roller screws, giving them a significant advantage in handling higher loads and shock loads.

- Roller screws are ideal for applications that require high force, repetitive cycles and long expected life. This can be especially critical in applications where most of the working time is spent on a small section of the thrust rod (like pressing & high-frequency oscillation).

Manufacturing Spotlight

Back to the basics of manual milling

If you’ve never operated a bridgeport milling machine, please watch this video. [End of Public Service Announcement]

But seriously though, the bridgeport is still a staple of prototyping shops everywhere. The knee mill is oldschool yes, but its insanely versatile given its size and cost. In fact, while we are at it dear reader, please head on over to Tom Lipton’s page and check out how much you can get done without CNC.

Tom also wrote a great book on machining and metalwork that is a practical goldmine for engineers.

Metalworking Sink or Swim: Tips and Tricks for Machinists, Welders and Fabricators (Volume 1)

There are some wonderful fixturing tips for dealing with flexible parts that anyone designing small plastics will appreciate.

American muscle cars live on because of Taiwanese expertise

One of the peculiar aspects of a global economy is how the maintenance of the most nostalgic elements of a subculture (read American muscle cars) can be outsourced thousands of miles away to a group of people that are almost all younger than the subculture itself. I was pretty surprised to learn that amid the pastoral landscapes just outside Hsinchu and Taichung there is a thriving automotive parts supply industry for the american muscle cars of the late 20th century. In some cases, the factories have the original tooling from GM still stamping out parts and panels. Wild, and awesome.

Failure Analysis

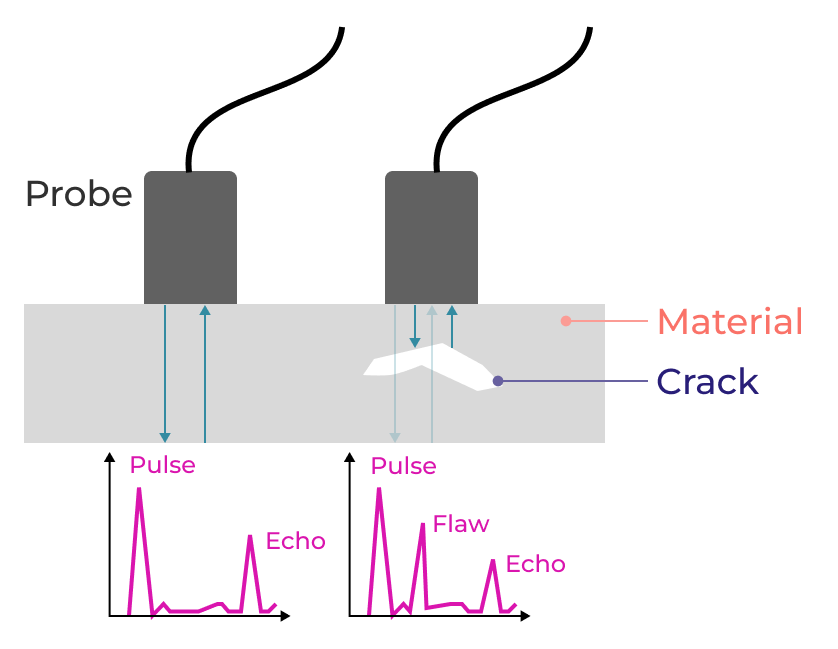

Back when the Titan submersible failed I was thinking alot about non destructrive testing methods for composites. I’ve barely had to do any of that work in my career outside of the occasional third party test on a large layup but its always been interesting to me, particularly in safety critical applications. So when I was bouncing around the internet yesterday and bumped into a pretty useful guide on ultrasound crack detection I figured I’d pass it along. This got me interested in the physics of crack detection in metals, which seems like just as much art as science. Just like ultrasound in medical applications, scanning relies on reflection of acoustic signals (transverse and longituninal waves) and the acoustic impedence of the materials being scanned. I made a handy diagram below to illustrate the concept.

In case you missed it

I recently posted about my top 5 engineering creators on youtube. Here’s the list!

- Steve Mould

- This Old Tony [my favorite!]

- Aaed Musa

- From Scratch

- Not An Engineer

That’s it for this issue, thanks for reading and good luck with your hardware projects!