Customer Success Story

AMP

Powering team CAD sharing and facilities design review for a platform enabling lower-cost, higher-performing recycling systems.

Read this whitepaper to learn how AMP leveraged Five Flute to share CAD, streamline collaboration and deliver a better finished product to their customers.

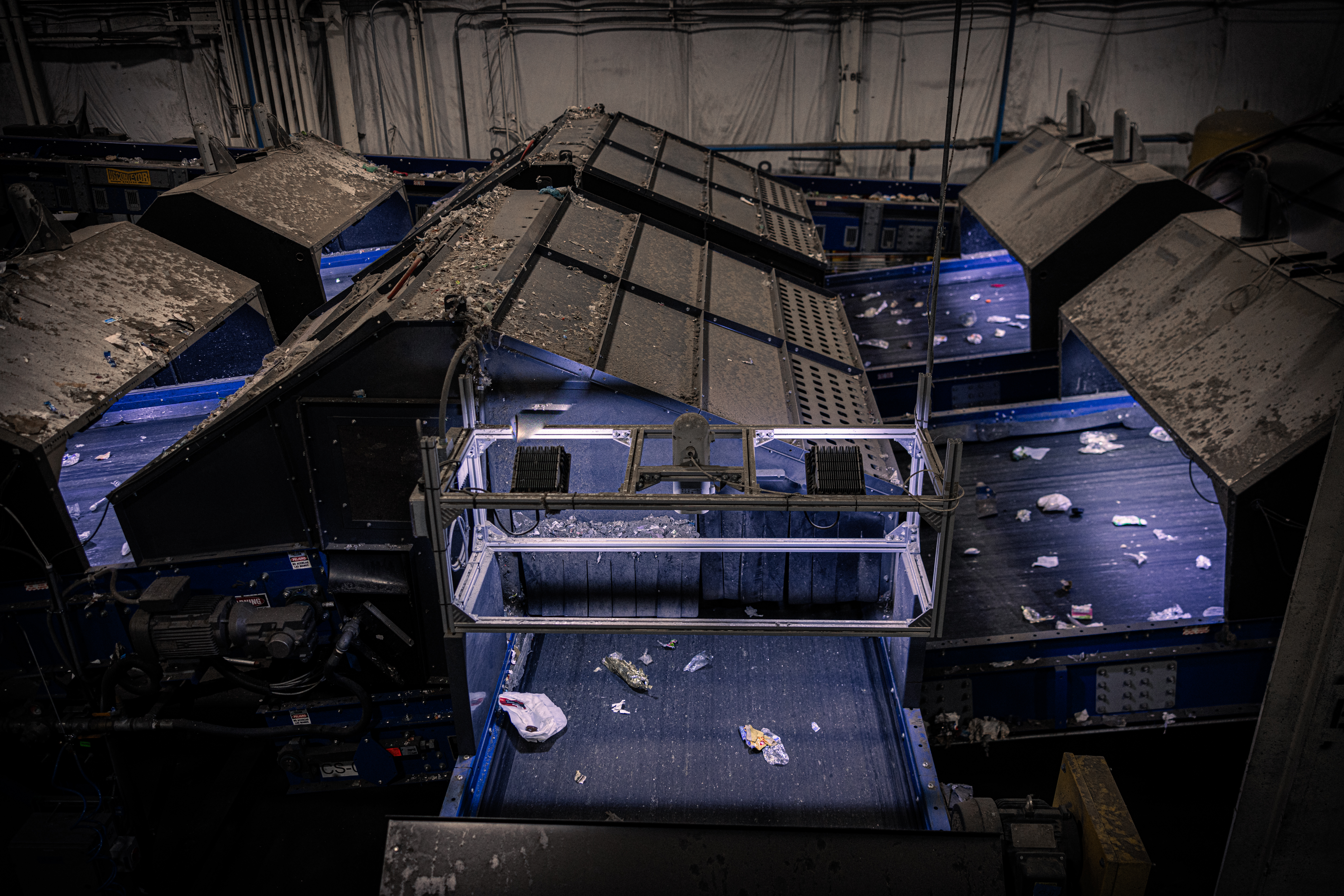

Customer OverviewAMP is applying AI-powered sortation at scale to modernize the world's recycling infrastructure and maximize the value in waste. AMP gives waste and recycling leaders the power to reduce labor costs, increase resource recovery, and deliver more reliable operations. The AMP engineering team designs bespoke recycling automation systems that leverage computer vision and AI to identify and sort recyclables. The work involves tough engineering problems that cross many disciplines—mechanical, electrical, optical, software, firmware AI, computer vision and more.

Customer OverviewAMP is applying AI-powered sortation at scale to modernize the world's recycling infrastructure and maximize the value in waste. AMP gives waste and recycling leaders the power to reduce labor costs, increase resource recovery, and deliver more reliable operations. The AMP engineering team designs bespoke recycling automation systems that leverage computer vision and AI to identify and sort recyclables. The work involves tough engineering problems that cross many disciplines—mechanical, electrical, optical, software, firmware AI, computer vision and more.

Photo courtesy of AMP

Why Five Flute?For the AMP team, collaboration is a critical component of the design process. Because each customer operates a unique facility, the team must adapt a suite of standard modules to work within the layout of the customer facility. AMP’s team of facilities design engineers own this process. To deliver a great product, facilities design engineers like Bobby McKenna need to make sure that everyone involved in the project understands the implications of the design on the operation of the customer recycling facility. Before Five Flute, the team built extensive slide decks with a series of annotated screenshots, and would use them to guide meetings and capture stakeholder feedback. The effort involved in communicating the details of the design to everyone impacted was significant, and it was cumbersome to share context and design issues with staff outside of the core engineering team.

How does AMP use Five Flute?AMP uses Five Flute as a drop-in replacement for the team’s old slide deck-based review process. The facilities design team can share the top-level CAD model with internal and external stakeholders and capture feedback asynchronously, enabling their entire development team to stand up full facility design reviews in under one week. By week three, Five Flute was already a part of the design process that unlocked a new level of participation and development velocity.

How does Five Flute help?Four months into its adoption of Five Flute, the speed of AMP’s design review process has increased dramatically. The team has uploaded and reviewed more than 30 assemblies, averaging less than two days between design reviews. This is what rapid iteration looks like! On top of that, Five Flute notably reduced the review preparation and meeting time.Here’s what senior facilities design engineer Bobby McKenna has to say about Five Flute.

Bobby McKennaSenior Facilities Design Engineer